The Gambia currently imports the vast majority of its medical equipment, and practical training and lab equipment for medical students is limited.

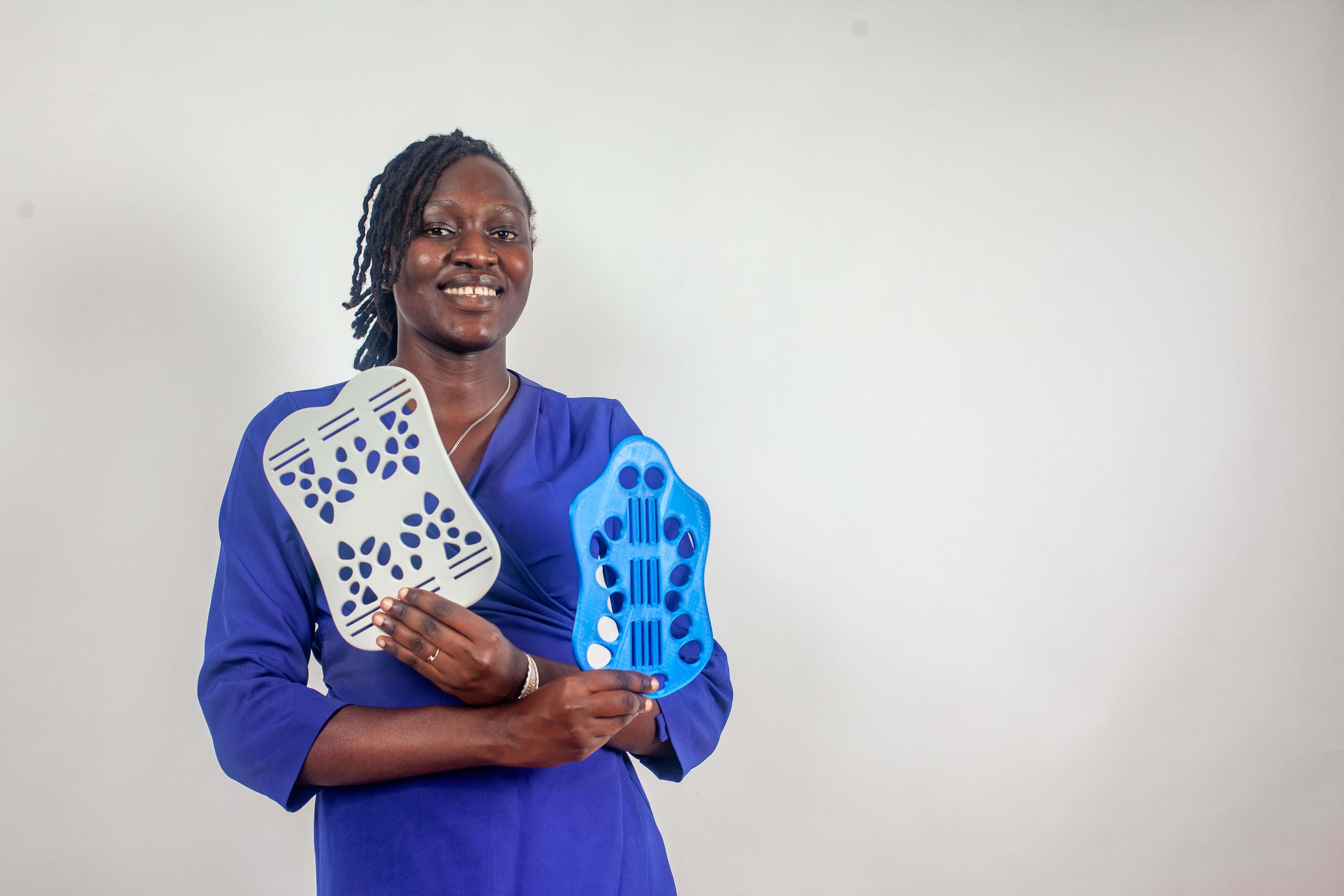

Mechanical and electronics engineer Juka Fatou Darboe identified areas where Make3D Medical devices can be used as an alternative to surgery, and where they can be used to modify existing devices to make them more culturally acceptable, more physician- and patient-friendly, and better suited to local climates than Plaster of Paris. After meeting her co-founder in The Gambia two years ago, their interest in technology and 3D printing brought them together to form Make3D Company Limited, out of which Make3D Medical was born. Their company designs and produces cost-effective medical equipment to treat fractures, such as braces, splints, connectors and spare parts for medical devices.

Juka and her team not only develop finished components and medical products that help doctors provide high-quality care without delays caused by importing and customs, they also teach medical professionals to make their own products. The company’s capacity-building packages include Make3D Medical hardware and software, training for staff, raw materials, and access to a central database of verified 3D designs. This allows hospitals and clinics to respond to needs in real time – if equipment breaks, components can be printed. When patients need structural support like splints and braces, they can be custom made.

In 2020, Make3D Medical developed more than 20 3D-printable devices in cooperation with various partners, including inhaler spacers, humeral braces and Y-connectors. To date, it has manufactured more than 1,000 elements for the medical industry in The Gambia.

Since being shortlisted for the Africa Prize, Make3D Medical has registered its trade name and is in the process of certifying its products with the Gambian Medicines Control Agency. This process will help increase the business’s credibility, which will also make scaling up to other countries in the region much easier.

“The practice of surgery in resource-limited settings is particularly challenging. We have identified areas where our devices can be used as an alternative to surgery, offering a huge cost saving to patients.”

Juka Darboe, Make3D Medical