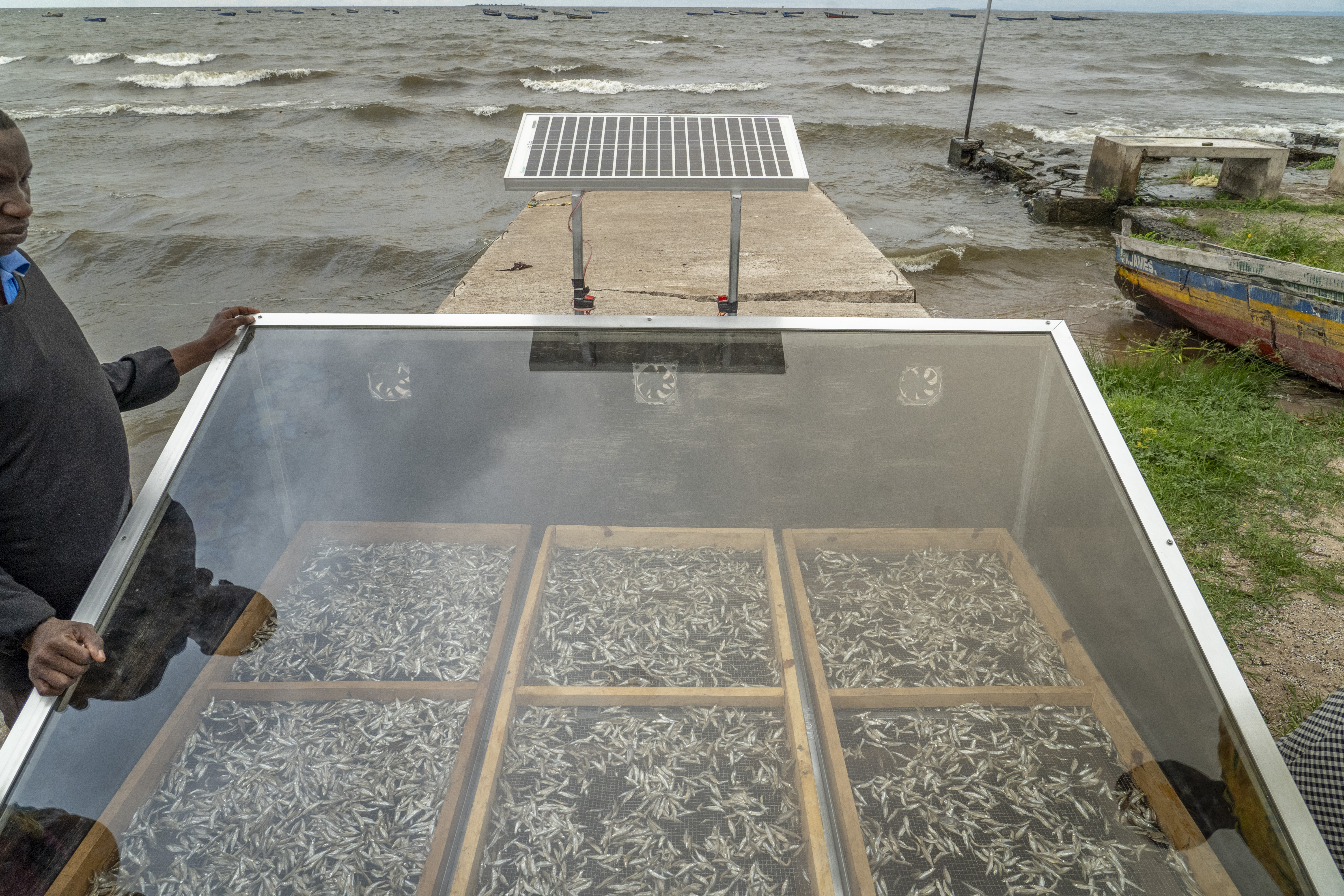

Developed by Tanzanian environmental and renewable energy researcher, Dr Evodius Rutta, the mobile solar-drying facility has multiple aluminum drying chambers (1200 x 1800 x 60 mm) with a mounted 18-watt solar panel powering three fans. This provides airflow through the chamber and out of a side vent. Inside the chamber are two layers of wooden drawers with galvanised steel wire mesh with the capacity to process up to 250kg of fish, which can be monitored through a clear glass window.

In Tanzania, dried fish, or Dagaa, is a popular food and major source of income for fish processors. However, small-scale fish processors, especially women, lose up to 50% of their fish harvest due to lack of drying and cold storage infrastructure. Most of these people rely on traditional fish processing methods such as smoking, salting and open sun-drying.

These methods are not always hygienic and can expose consumers to food-borne diseases. Unlike other existing fish processing practices, which can take up to 12 hours, the MAVUNOLAB Solar Dryer can process fish in less than six hours. This significantly reduces post-harvest losses and contamination, increases income and improves the fishing value chain.

The current version of the solar dryer, developed by Dr Rutta and his team, is being tested and deployed to small-scale fish processors in Lake Victoria, western Tanzania. Future versions of MAVUNOLAB Solar Dryer will be adapted for drying and processing fruits and vegetables. Dr. Rutta also plans to launch a cold storage facility to offer cooling services for people who fish in Lake Victoria and other parts of Tanzania.

Most fish processors in Lake Victoria are women, who lose income due to post-harvest loss and spend too much time on prolonged drying processes. MAVUNOLAB SOLAR DRYER enables these women to have more time for other socio-economic activities, including taking care of their children and engaging in other income-generating activities.

Evodius Rutta