Unlike traditional solar dryers, the hybrid technology combines solar power and biofuels, enabling year-round use, avoiding farm losses during adverse weather, and boosting food security for farmers in Kenya.

James’ story

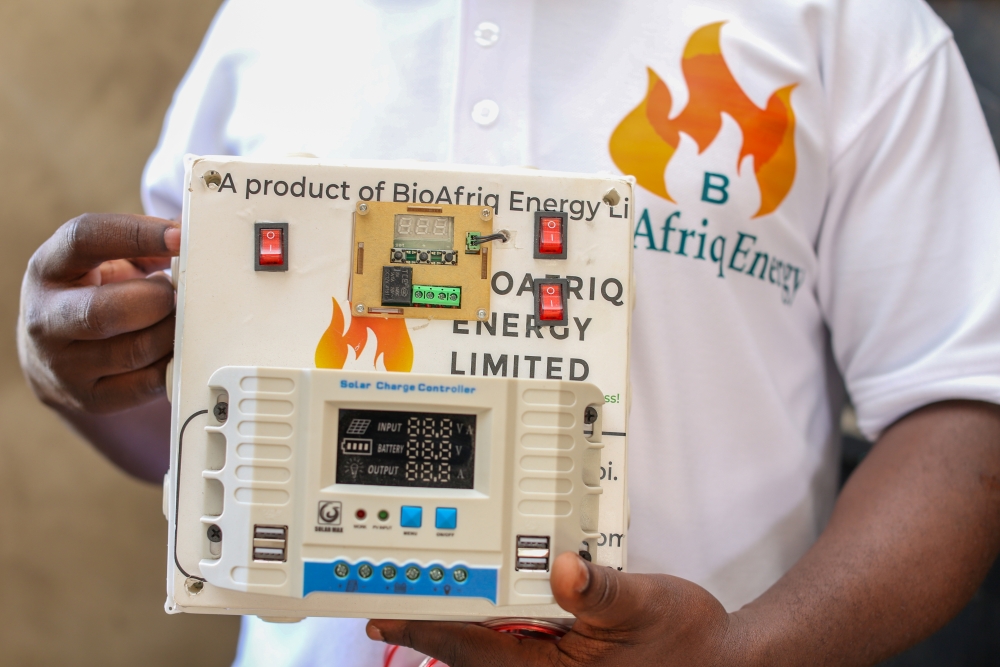

James Nyamai grew up in Nairobi, Kenya, where he faced both personal and professional challenges. After surviving meningitis as a child and losing his hearing, he went on to earn a mechanical engineering degree. He worked in aluminium manufacturing before venturing into entrepreneurship in 2012, initially with vegetable and poultry farming, before founding his own company BioAfriq Energy in 2017.

James started research on biomass fuels in January 2017 aiming to reduce his reliance on charcoal used to provide heat for chicks at night on his poultry farm. His mother, also a smallholder farmer, used a traditional solar dryer to dry pumpkins to make pumpkin flour. When, in the same year, her dryer failed, James realised he needed to find a solution that was not dependent on just one source of energy.

The innovation

After founding BioAfriq, James spent the first two years of his business on research and development and learned that traditional solar dryers were often ineffective during the rainy season.

He looked at alternative, renewable sources of fuel, such as biomass fuels made from maize cobs and rice husks, that could be used during adverse weather. He then combined this biomass power solution with solar power, and the Hybrid Solar Dryer was born, a renewable energy dryer that is functional year-round.

My mother was a victim of a Ponzi scheme selling pumpkin seeds, promising to buy back the crop once grown. But when the time came, the buyer was nowhere to be seen. My mother had all this crop that was going to waste, and I thought, why not dry it to create pumpkin flour and have something different to sell?

The BioAfriq Hybrid Solar Dryer includes a temporary structure (which is the dehydrating chamber) that has a UV-treated poly covering for heat retention and a black floor liner for heat absorption. The drying system then attaches to this, using solar-powered fans that circulate warm air; a biomass heating system using eco-friendly fuel made from waste agricultural biomass; and a heat exchange system that prevents contamination. The dryer has a digital control system that automatically regulates the temperature required for different crops to ensure consistent drying and to preserve nutritional value.

The system allows farmers to extend the shelf life of dried produce by up to 12 months, enabling them to sell dried foods or process them into products such as flour or packaged snacks.

The use of biomass fuels using agricultural waste from the farmers’ farms, such as briquettes made from maize cobs, is cost effective. and environmentally friendly, as agricultural biomass left to decompose emits methane gas into the atmosphere.

Making a difference

In Kenya, an estimated 33% of produce is lost annually because of droughts, floods, pests, and disease. BioAfriq’s hybrid dryers have already made a significant impact in addressing this issue. First introduced in 2020 with just 20 farmers in Machakos County and Makueni County, the technology now supports over 6,500 farmers, reducing post-harvest losses by up to 40%. This innovation has not only increased farmers’ incomes but also contributed to strengthening Kenya’s food security.

Now operating out of a production facility in Machakos County, James is aiming to impact at least 12,000 farmers within the next three years. Additionally, BioAfriq plans to expand and introduce its technology to other farmers in East Africa.